NEWS RELEASE February 2020

Will the $50 billion FGD Market Go Up or Down?

More than $50 billion per year is being spent on removing SO2 from the stacks at power plants. The flue gas desulfurization (FGD) systems are operating on combustors burning coal, biomass, and waste. Eighty percent of sulfur is being removed by wet scrubber systems using ground limestone. The calcium sulfate is then used in gypsum wall board. About 15 percent of the sulfur and other acid gases are removed in wet or dry lime systems. The remaining 5 percent is captured with sodium, amines, magnesium oxide and some other reagents.

The future of this market is dependent on the climate change initiatives. A program oriented around the acceptance of the doomsday scenario would seem to eliminate all but biomass fired boilers very quickly. However, thanks to technology and logical breakthroughs it now appears that the best way to deal with the problem would be to suck the CO2 out of the air. A combination of planting a trillion trees and co-firing biomass with CO2 sequestration would be better than wind or solar. The extent to which biomass is cofired (0-100%) and the amount of CO2 which is sequestered will be part of an opportunistic and flexible strategy which is made possible by technologies addressed in the following news releases

Opportunistic Biomass - CCS Program is the Route chosen by the UK and Japan

Climate Change and the Quality of Life

The Opportunistic Antidote to the Climate Change Doomsday Scenario

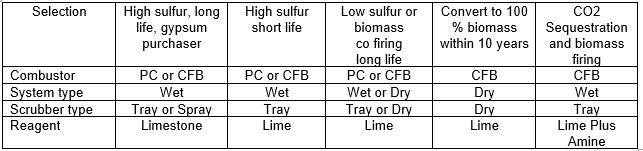

This strategy affects the selection of FGD systems. The full limestone-gypsum forced oxidation wet system is very capital intensive and is most attractive with high sulfur coals. If biomass is co-fired the quantity of sulfur is reduced. Limestone is economically attractive if there is a market for gypsum and the plant life will be long. Lime is a better choice if the plant life will be short because it requires a much lower investment in scrubbers. The capital expense for producing gypsum can be eliminated with natural oxidation and chemical fixing of the waste for safe disposal as landfill.

An alternative to natural oxidation wet lime is dry scrubbing with lime injection into a spray dryer or dry reactor. If circulating fluid bed boilers are used for combustion the limestone in the boilers plus the lime in the dry scrubber system remove the acid gases.

The selection of CFB boilers is also dictated by the ease of firing biomass. Here are equipment choices depending on conditions.

The coal fired boiler operators, boiler and FGD suppliers can take a reactive role or they can support the opportunistic Biomass-CCS model and select the appropriate FGD systems initially which will be the most adaptable. The Opportunistic Biomass CCS program will result in a larger market for CFB boilers and lime.

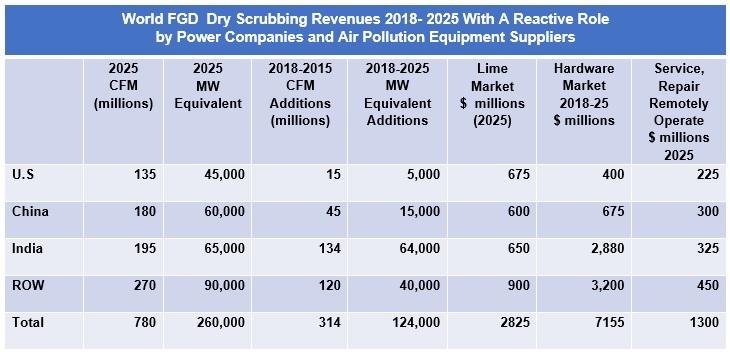

With a reactive role by power companies and FGD suppliers the revenues from sale of lime, hardware and service for dry scrubbers in the 2018-2025 period will be $11 billion or $1.6 billion per year. This will increase slightly to has high as $2 billion per year in the 2025-2030 period and then decline as renewable power generation starts to take more market share. This decline will continue in the 2040-50 period. In 2050 the revenues are likely to be less than $700 million per year.

With a proactive program the dry scrubber sales will be higher and for a greater duration. Lime will be preferable to limestone as the reagent.

The McIlvaine Company is continually assessing this market to determine the potential revenue for systems, scrubbers, liquid-solid separation, fabric filters, valves, pumps, fans and other components. Customized supplements can be provided to the basic FGD Markets and Strategies.

http://home.mcilvainecompany.com/index.php/markets/air/n027-fgd-market-and-strategies

For more information call Bob Mcilvaine at 847 784 0013 or email him at This email address is being protected from spambots. You need JavaScript enabled to view it.