NEWS RELEASE September 2022

Semiconductor Ultrapure Water is a $3 billion Air, Water, Energy, (AWE) Market

Semiconductor investment in ultrapure water is increasing at a rate of 9% due to the

- Increasing quantities

- Increasing quality

- ESG considerations

The market is split between discrete and process applications. Process includes water pretreatment, reverse osmosis, ion exchange and the related valves, pumps, and chemicals. The discrete applications include ultrapure water as the carrier of chemicals used at the tools. Small valves vacuum pumps and cartridges are used.

Four million gallons of water can be used per day in a 200 mm wafer plant. This increases to up to 10 million gpd in a fab using 300 mm wafers. As the linewidths are reduced there is more on a chip which needs to be treated and therefore more water needs to be used.

It is also important to take into account the need for greater and greater water purity as the linewidth shrinks.

In terms of flow quantity and product investment what is important is the quantity of water being circulated and not the quantity entering or leaving the plant.

Fab Projects and Water Requirements

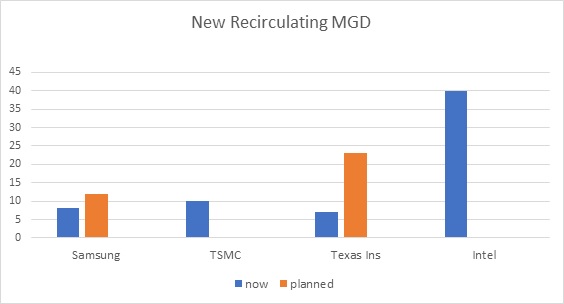

In the U.S. there are a number of new fab projects which will require increases in recirculation of more than 100 mgd. Intel alone will be adding 40 mgd.

This chart covers projects underway and those for which sites have been chosen but no final commitment made. This table only includes major projects.

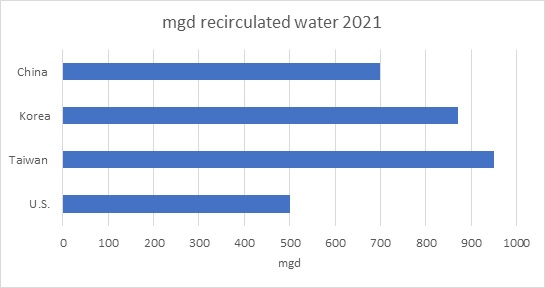

The U.S. is presently behind three other countries in terms of recirculated fab mgd. The recently enacted CHIPS act will narrow the lead of others such as Taiwan but there is a long way to go.

The U.S. presently has 500 mgd of water recirculated at fab plants compared to 950 in Taiwan.

The McIlvaine Pump, Valve, Ultrapure Water, RO, UF, MF, Sedimentation, Cartridge, Air Filter, Cleanroom Hardware, Cleanroom Consumables, IIoT and Treatment Chemicals reports provide detailed forecasts of AWE products used in semiconductor manufacture. There is also Cleanroom Projects with information on few plants as well as those in operation.

These services are described at www.mcilvainecompany.com

Bob McIlvaine can answer your questions at

847 226 2391

This email address is being protected from spambots. You need JavaScript enabled to view it.