NEWS RELEASE JUNE 2016

$23 Billion High Performance Pump Revenues Projected for 2017

Nearly half the industrial pumps which will be sold next year will classify as high performance. According to the latest forecast in Pumps: World Markets sales of high performance pumps in 2017 will reach $23 billion.

The criteria for this category are both severe and critical service. Those pumps which have to be engineered to withstand corrosion, abrasion, high temperature and pressure are classified as in “severe service.” Those which must meet high purity and safety requirements such as found in the food and pharmaceutical industry are classified as in critical service. High performance pumps are further distinguished by being specially engineered and not being stocked commodity products.

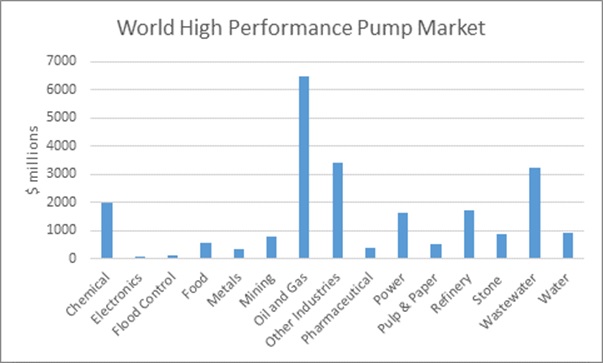

These pumps are used in many different industries. The oil and gas applications are the largest with predicted purchases next year in excess of $6 billion. A relatively small percentage of municipal wastewater pumps are classified as high performance. But, since the wastewater pump market is so large, even a small percentage results in a $3 billion annual high performance pump market. The chemical and refining industries will also be major purchasers. The power industry will be a bigger market in Asia than in other regions. A number of new ultra-supercritical coal-fired power plants are under construction. Each will have millions of dollars of high performance pumps.

International suppliers have a large share of the high performance pump market and a smaller share of the commodity pump market. It will continue to be easier for an international company to penetrate a local market with its high performance products rather than its commodity products.

Greater profits can be reaped from high performance pump sales because of the higher gross margins. On the average it is estimated that the gross margin from a high performance pump sale is 35 percent versus just 25 percent for a commodity pump. So, despite the smaller market size of the high performance pump market, the gross profit will be higher.

Each industry can be segmented into five different uses:

| Use | High Performance Needs |

| Water Intake | Extraction from wells, lakes and streams involves some pre-treatment. High performance pumps are required in some pre-treatment schemes and where intake water is corrosive e.g. some wells. |

| Cooling | Cooling is either once through or recirculating through cooling towers. There are few high performance pump requirements. |

| Combustion | Power producers and industrial plants requiring steam and power need high performance boiler feedwater pumps. |

| Process | Many process schemes incorporate high performance pumps to move or convert a product. |

| Wastewater | Wastewater with abrasive solids or corrosive chemicals requires high performance pumps. |

In the power industry, combustion is the largest application due to the boiler feedwater requirements. In most other industries, the process use is the greatest. The processes can be further segmented by function.

| Function | High Performance Pump Needs |

| Transport to or from storage | Medium |

| Transport to the next process | Medium |

| Play a role in the product creation | High |

| Utilities such as lubrication, hydraulic power, heating and cooling | Low and not included in the forecasts |

| Extraction and measurement of samples | Low |

The processes which play a role in product creation can be further segmented by the type of change with which they are involved.

| Process | High Performance Pump Needs | Examples |

| Mixing | medium | Fluid-to-fluid or gas-to-fluid e.g. wastewater pump which moves and aerates or ammonia pump which disperses fluid in gas stream to react with NOx |

| Heat/Cool | medium | Cryogenic and LNG high temperature foods which must not be damaged by transport |

| Separation | high | Feed and discharge from centrifuges, filter presses, clarifiers. In wet mineral size reduction and separation, there are highly abrasive slurries. |

| Dehydration/ Evaporation | high | Slurries created in crystallization, pumps at high pressure to move liquor through spray drier nozzles |

| Reaction/Absorption | high | Varying temperatures, fluid state and pressure needs of the reactor or absorber. Function is often to recycle and disperse. |

| Cleaning or blasting | high | Develop pressures to clean scale from castings and fracture shale |

| Disinfection | medium | Dispersions of large quantities of chemicals in liquid |

| Displacement | high | Water injection to displace oil |

Pump suppliers should seek to understand as much as possible about the industries, processes and functions within those processes where their pumps might be used. The pump designers can provide solutions and not just hardware if they can first understand the needs. Sales and senior management need to understand the processes in order to better predict future market opportunities.

For more information on N019 Pumps World Market, click on: http://home.mcilvainecompany.com/index.php/markets/2-uncategorised/116-n019