NEWS RELEASE OCTOBER 2016

Utilizing the Excess Coal-fired Boiler Talent in the U.S.

The U.S. is not building new coal-fired power plants and will be shutting down nearly 70,000 MW of existing power plants. There is uncertainty regarding the remaining 190,000 MW depending on clean power regulations. The result of this shrinkage is a large excess of coal-fired boiler talent in the country. Two options for beneficial use are to channel this talent into:

- Other types of power generation activities

- Coal-fired boiler power generation overseas

This is easier said than done. This talent needs to gain new knowledge and to be integrated into to new organizational structures. McIlvaine believes that the best way to gain this knowledge and to create a structure is through “Wise Crowd” Decisions.

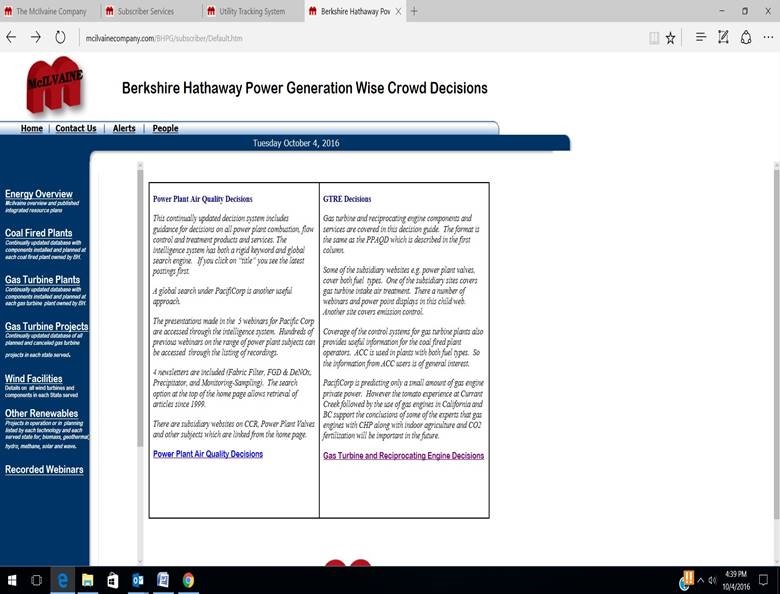

McIlvaine has created a system to cover all power generation knowledge regarding Berkshire Hathaway (BH).

The ultimate goal is to create systems for the 300 largest power plant operators worldwide. These systems unleash the potential for “wise crowd” decisions through digital interconnection and delivery of the 4 knowledge needs: Alerts, Answers, Analysis and Advancement. These systems can be used by the U.S. coal-fired boiler talent to either transition to new types of power generation decisions or to bring their talents to the international coal-fired power generation industry.

Transition to Other Types of Power Generation Facilities

Already much of the coal-fired talent has been redirected to work on gas or renewable energy activities. There is an internal restructuring at most large power generating companies. Berkshire Hathaway (BH) has been building gas, solar, wind and biomass plants. To utilize coal-fired talent for the other types of generating facilities there may be relocation and training requirements. The “Wise Crowd” Decisions systems can positively address both challenges.

Relocation: With the internet of things and the delegation of certain tasks by specialty some of the coal-fired talent may not have to relocate. Let’s take water monitoring systems as an example. The October Monitoring and Sampling newsletter is one of the tools in the BH “Wise Crowd” Decisions. It includes an analysis of Hach pH analyzer decisions made at the Mid-American Neal coal-fired power plant. It includes Hach water quality analyzer decisions being made at the PacifiCorp North Umpqua hydro plant and in the case of NV Energy the groundwater program for the Muddy River plant.

Specialization will minimize the need for relocation: One of the Mid-American coal people could be a leader in the pH and other water quality analyzer decisions for all the coal, gas, turbine, geothermal and hydro plants.

The hydro plants have further synergy in processes such as intake screens for coal and gas plants. With the fish ladders and other steps necessary to protect wildlife, the PacifiCorp hydro people have a number of in-house experts plus the modus operandi to work with outside testing firms. The fossil plants are challenged with new federal regulations impacting water intakes and discharge to reduce harm to fish populations. In the October Monitoring and Sampling newsletter, several hundred individuals at PacifiCorp and their contractors involved in this activity are identified. Power Plant Air Quality Decisions (PPAQD) has recorded webinars with companies such as Ovivo making presentations on screen designs to protect fish at coal-fired power plants. Ovivo is also involved in the hydro plants. It would, therefore, make sense to create a BH team which deals with fish protection at all the plants.

Bird kill is a concern with wind turbines. The BH hydro wild life protection expertise will be quite valuable to Mid-American who is building 3000 MW of new wind turbine facilities.

Training: The coal-fired talent which switches from coal to gas turbines immediately has access to Gas Turbine-Reciprocating Engine Decisions to select gas turbine inlet filters and to maximize their performance the talent can evaluate the negative impact of rapid cycling on valve selection. Aspects of the HRSG, SCR and monitoring are different and can be quickly understood with the access to hundreds of hours of webinars, and organized analyses and case histories. There are separate child webs on some components such as power plant valves which cover all fossil and nuclear requirements.

Coal-fired Power Generation Overseas

The goal is to create systems identical to the one for BH for all the large power plant operators around the world. The fact that BH and a large Indian utility are using the same system opens new markets. McIlvaine has conducted five webinars for PacifiCorp focused on reductions in NOx without the use of SCR. New NOx regulations in India will place many plants in the same position as PacifiCorp. PacifiCorp will be doing some testing and is likely to become the world leader in achieving NOx reduction without full SCR. This expertise is exportable.

The talent and the systems utilized by U.S. coal-fired boiler operators can be put to good use by coal-fired power plants in other countries. More than 90 percent of coal-fired generation takes place offshore. U.S. utilities do not have to own international generation facilities in order to leverage their coal-fired talent. They can provide operating support. If a utility creates specialists for its own plants and maximizes the information generated by machines, it can cost-effectively assist international plants to follow suit.

McIlvaine Decision Systems can be very helpful in supporting these international operations. Operators in many international coal-fired power plants will not speak English. However, if the basic technical options are defined in the local language, then the important communications are possible. In some cases, this means first clarifying the options. There was confusion among catalyst cleaning, catalyst rejuvenation and catalyst regeneration. It took a 40-minute webinar with catalyst suppliers and others to agree on definitions and terminology in both Chinese and English.

The U.S. has been a leader in developing cost effective clean coal technology. This resource should be leveraged rather than lost.

For more information, click on: 44I Power Plant Air Quality Decisions (PPAQD)

For more information, click on: 59EI Gas Turbine and Reciprocating Engine Supplier Program.

For more information on interconnection programs contact Bob McIlvaine at 847 784 0012 ext. 112 This email address is being protected from spambots. You need JavaScript enabled to view it.